This beer is fermented with our house ale yeast.

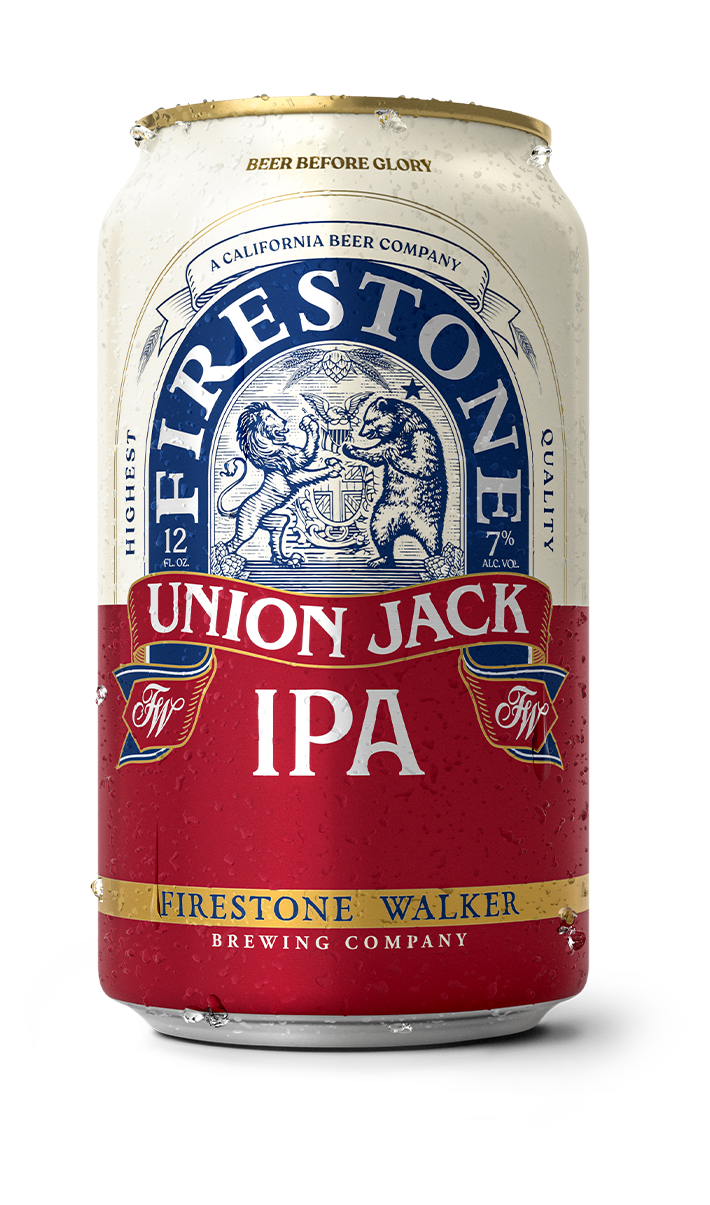

Huge flavor that packs a punch. This is Union Jack—an icon of the West Coast IPA style, for those who like their beer loud and proud.

Availability

Our Original West Coast IPA

-

Simcoe

One of the most popular hops for both the craft beer and homebrewing industries. Great for bittering and packed with stone fruit, pine, and citrus zest aromas.

- Aroma

- Pine, citrus and passion fruit

- Region

- PNW

-

Chinook

Originally bred as a bittering hop back in 1985, but has recently been recognized as a dual-purpose hop that is well rounded and suited for many different styles.

- Aroma

- Pine, Grapefruit, berry

- Region

- PNW

-

Centennial

Named after the centennial anniversary of Washington state, this hop is incredibly well-rounded and useful for bittering, flavor, aroma, and dry-hopping.

- Aroma

- Fruit loops, Orange blossom and pine

- Region

- PNW

Just a hint of Crystal malt makes this beer true to the West Coast IPA roots as well still being a modern beer.

Fermented in Stainless Steel

The Art of the Process

Milling starts the beer making process by splitting open grain, mostly barley, making it ready for mashing. We use a wet mill, which is more efficient and gentler on the malt. During mashing, the split malt combines with hot water to convert the starches into fermentable sugars. This conversion is made possible by the enzymes that are in the malted grains.The mash then moves to the lautertun, where the sugary liquid (wort) is separated from the malt, the spent grain is then sent to local ranchers for cattle feed.

The kettle is where the wort is boiled using steam, ensuring sanitation and eliminating potential off-flavors. This stage is also when hops are first added, contributing bitterness and aroma to the beer. Next, the wort moves to the whirlpool, where additional hops can be added, and solids like proteins and hop particles are separated. From there, the wort is cooled, oxygenated, and transferred to the fermenter, where yeast is introduced to begin fermentation.

Fermentation is where yeast converts sugars into alcohol and CO2, the most crucial step in creating beer. This stage is closely monitored, ensuring that each beer’s unique characteristics develop fully. Depending on the beer style, this step can take several days to weeks. All FW beers will use one of three yeast strains, our house ale, lager or hazy yeast.

We use a dry hop cannon that employs CO2 pressure to introduce hops directly into the top of the fermenter, giving our IPAs an intense hop aroma without adding additional bitterness. This technique creates the signature hoppy character found in many of our beers. The result is a bold aroma, particularly in our IPAs, while maintaining a balanced bitterness profile.

All Firestone Walker beers go through our centrifuge to eliminate any large particulate (hops, yeast or protein). Then all the beers are carbonated on the way to the bright tank. If the beer is clear, it will also be run through the polish filter. At the end of filtration, the beer will be ready to go into package and is ready to drink.

Throughout the brewing process, our expert lab staff plays a crucial role in ensuring the quality of our beers. They conduct extensive testing on every measurable aspect, from specific gravity and pH levels to bitterness and aroma compounds. This meticulous approach includes sensory evaluations, allowing us to assess the taste and overall flavor profile of each batch. By combining scientific analysis with expert tasting, we maintain our commitment to delivering exceptional quality and consistency in every beer we produce.

Once the beer reaches its final stage, we package it in bottles, cans, or kegs, carefully preserving its quality and freshness. Our commitment to sustainability shines through this process, as we use recycled materials and energy-efficient practices to minimize environmental impact. We also invest in state-of-the-art equipment to reduce waste and enhance packaging efficiency, reflecting our dedication to brewing exceptional beer while caring for the environment.

We prioritize cold storage throughout the entire distribution process to ensure our beer reaches you in the freshest condition possible. This careful handling preserves the beer’s intended flavor profile, aroma, and overall quality, maintaining the integrity that we craft into every batch. Because of this commitment to freshness, we always recommend enjoying our beer as soon as possible to experience it at its very best!

Related Beers

You May Like

Stories